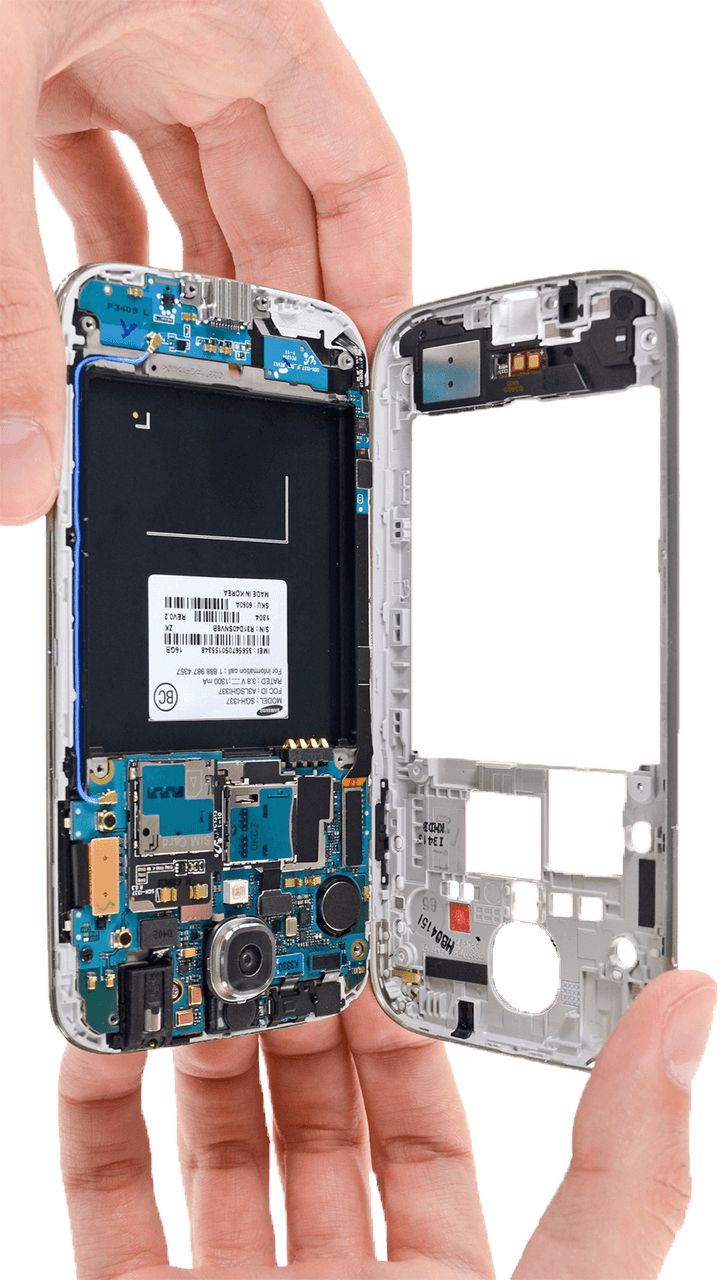

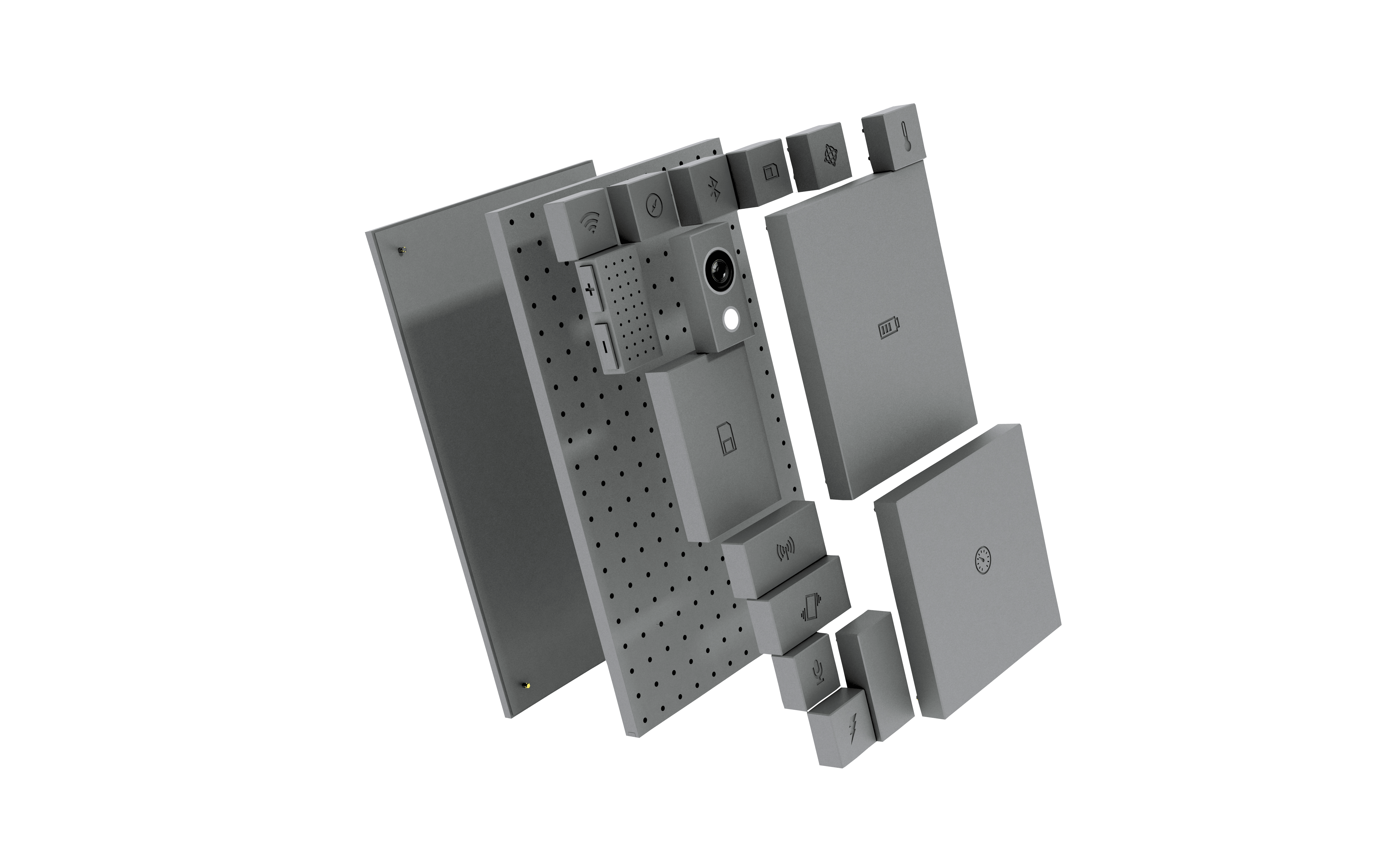

Many argue that modular phones are not a viable option. Consumers demand speed in their electronic products. However, even one extra millimeter between motherboard components can cause a serious reduction in processing speed. Therefore, in small devices, such as smartphones, as many components as possible are all packed into a single unit. While this level of integration doesn’t facilitate repair, it does allow devices to run fast. Modular phones may have difficulty reaching the processing speeds to which consumers have become accustomed.

Even if a successful modular phone is built, logistic limitations may limit its viability. Current smartphone manufacturers have not expressed interest in the modular phone concept. Add to this the challenges associated with creating a wide-scale distribution network for modular components, and it would appear that the modular phone is unlikely to be available any time soon.

Although Google’s Project Ara is a major step forward in modular smartphones, the fundamental issue of highly integrated, not easily repairable, motherboards remains. Furthermore, this technology has thus far focused entirely on the development of a modular phone and does not address the countless other devices that contribute to e-waste.